Full static control on flexoprinting machines

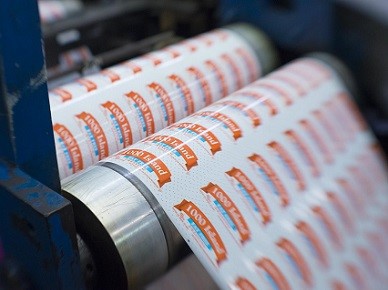

Flexographic printing lines as well as other printing presses are developed to produce flexible packaging in a variety of colours and finishes at high speeds. You can recognise static electricity by experiencing static shocks or seeing sparks as a discharging effect also printing issues like the following can have static as a cause:

- Ink mist

- Ghosting

- Fuzzy printing due to static

- Particles on the print

- Dust attraction due to static

- Print defects due to static

- Overspray due to static

All effects can be static electricity(high-voltage static) related issues. Static charges can create problems in many sections of the flexoprinter or flexopress.

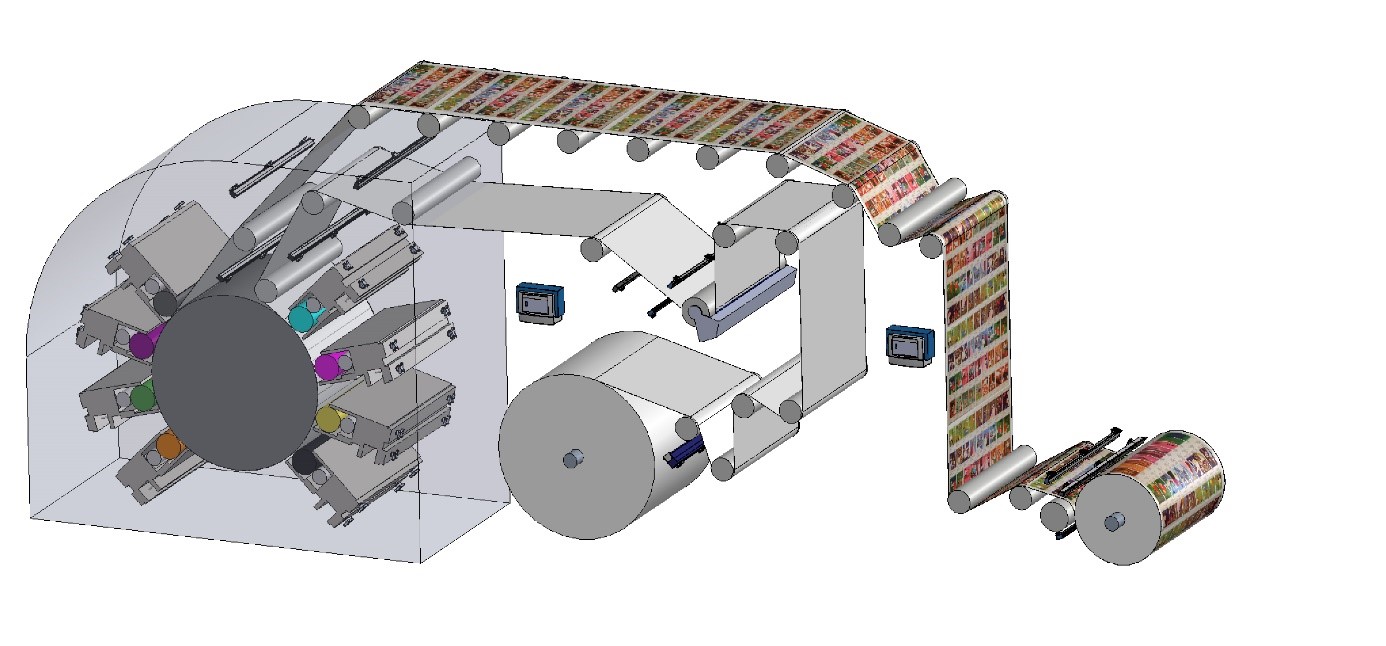

Discharging in Flexoprinters

Discharging the web directly after the unwinder will prevent that a static charge will attract dust particles. Also operators will not get any shocks while passing or touching the web. When the film passes a corona treater a massive static charge is created by the corona unit on the material. After the Corona treater a discharging is recommended(in closed loop feedback, optional).

If the flexoprinting section is indicated as Ex-area because solvents are used, static charges on the material can ignite the gas and cause a fire. Neutralising before the material touches the central drum is done by an ATEX approved static eliminator; the Performax IQ Easy EX.

Inside the printing section the material is passing multiple rollers and static electricity is re-created. Directly after the material is releasing from the central drum the material is again neutralised by ATEX approved static eliminators.

An important issue for ionisation bars in a printing machine is pollution. Cleaning is essential for the correct operation of the ATEX certified bars. The level of pollution can be controlled and monitored by the Simco IQ Manager system. Also the level of efficiency will be monitored and controlled so that you are sure that discharging will take place.

If the efficiency sinks below a pre-defined static level the IQ Manager will warn the operator to clean the static eliminator. You can see how to clean the anti-static-bars here.

After the printing section the material is re-charged again in the dryer. You can again place optional anti-static eliminators to neutralize the static charge before the film goes to the next section of the machine.

Note: Drawings and pictures do not show the application one to one, but clarify the situation and approach reality

On the winding station, static eliminators are installed to neutralise the material during winding, this will also prevent possible static shocks to the operator that performs the roll change. Another effect that can be prevented by discharging the material is the telescoping end roll effect.

In-line measuring and datalogging of static charge levels during winding can be used in quality reporting. The IQ Manager System can be directly connected to the PLC of the flexoprinting machine via Fieldbus connection. An alarm level alerts the operator in case the static charge reaches a dangerous level. This is how the IQ Manager System provides all essential information to maintain high speed, high quality and competitive flexoprinting.

Interested to learn more about the effect of static electricity?

Find a Simcorepresentativenearyou in the contact section or subscribe to the Simco Europe Youtube channel