Static electricity creating fire in coater section!

Manufacturers of packaging can experience multiple fires in their coating section caused by sparks from high static charges. Operators facing this issue turn to industrial antistatic solutions to help solving these static problems.

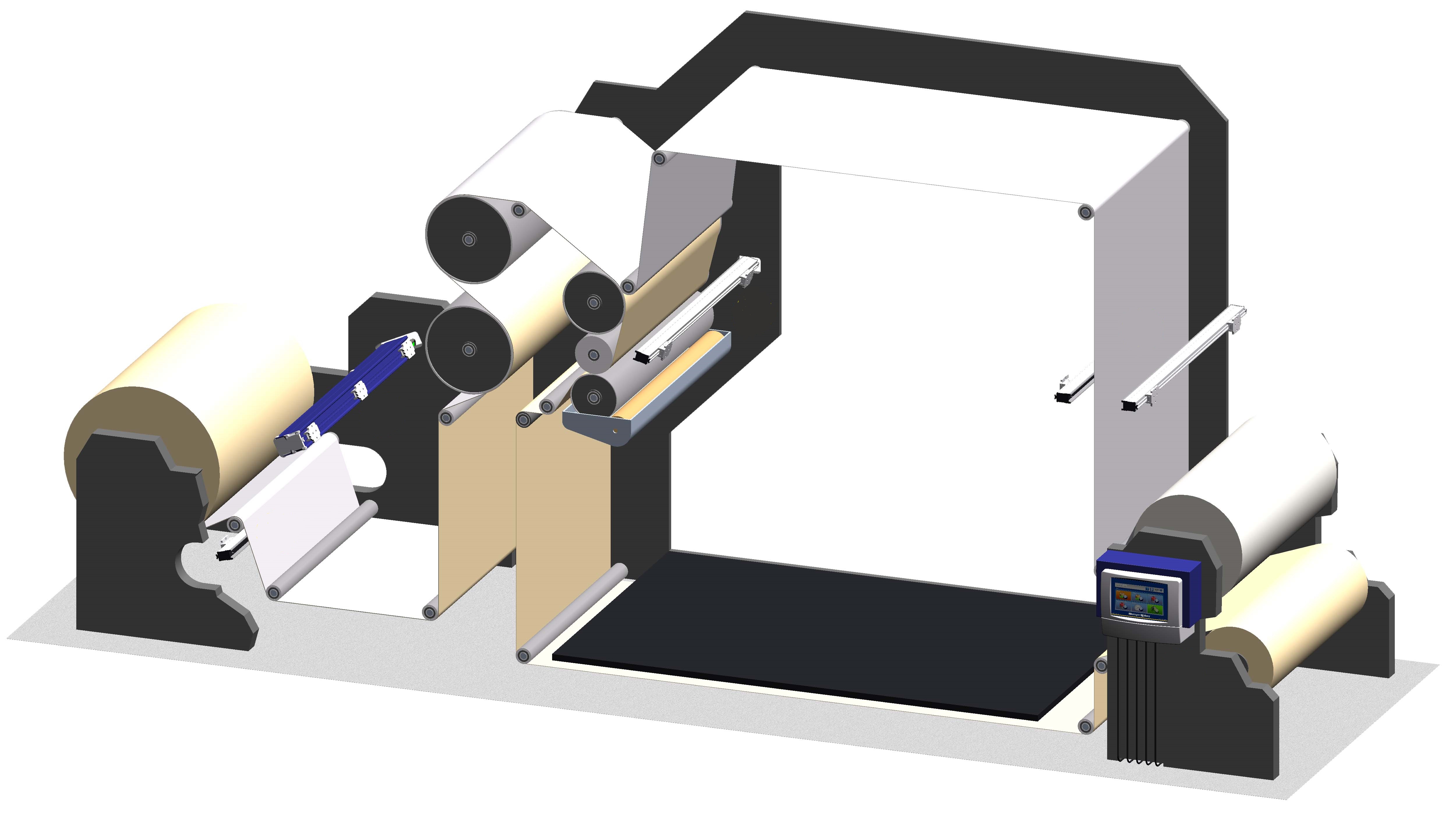

Each machine section can require different static eliminators as the distance to the material varies. Also different type of rollers which the material passes influence the level of static charge on the web. Special attention for safety is required when it concerns the Ex-area, where only ATEX-approved electrostatic eliminators are allowed.

Different measurements must be made to learn exactly where the static is generated and discharging is necessary. To measure the exact static charge a handheld FMX field (static) meter is needed or an IQ Sensor bar for in-line measurement.

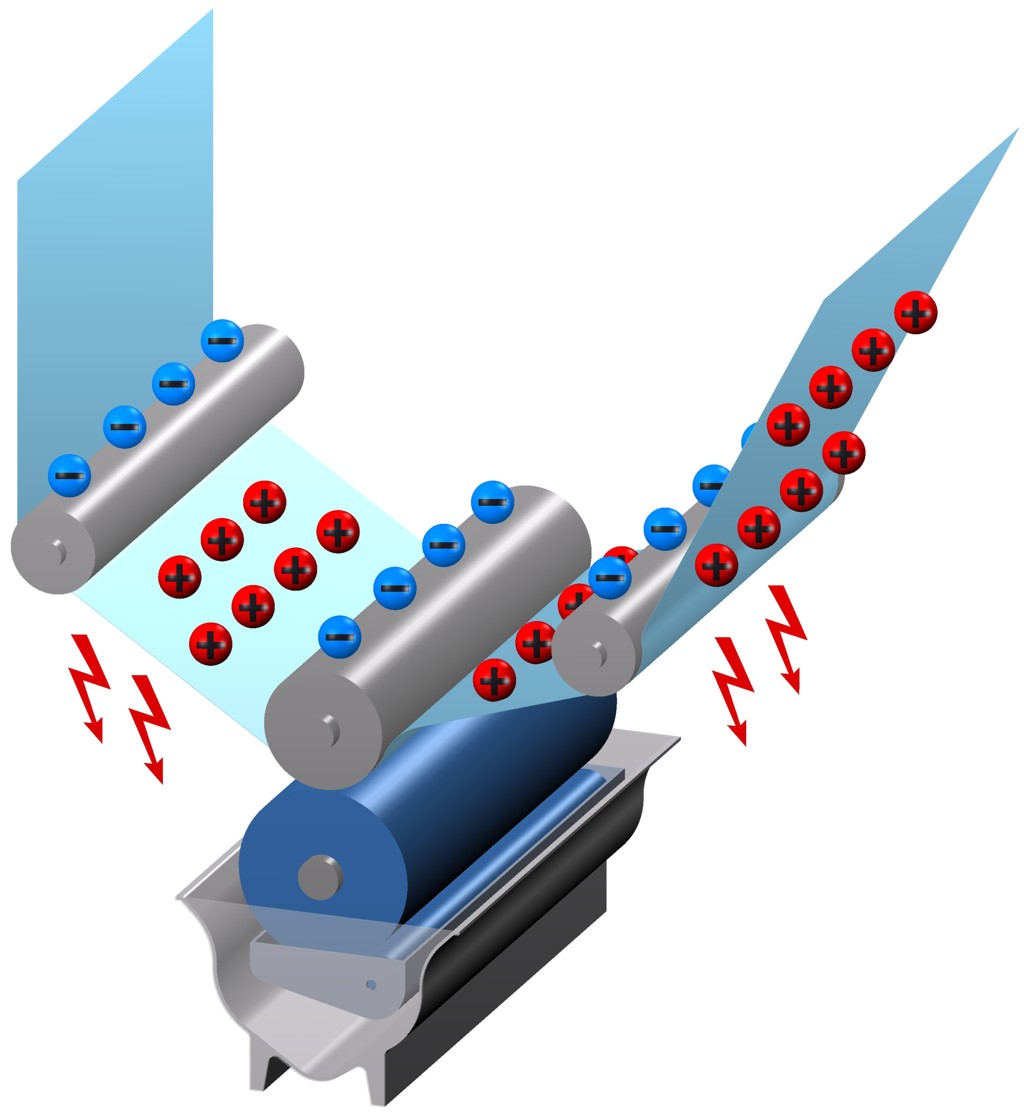

Unwinding plastic film can create static charges up to 20kV or more and the web needs to be neutralized directly after unwinding. Installing a high performance discharging bar also prevents that static charge will attract dust particles. If the material passes a corona treater, a massive static charge is created on the material and a discharging section (in Close Loop Feedback; CLFB) is recommended. Before the material goes into the coating section (ATEX-zone), both sides of the material require discharging to prevent the existing static charge acting as a possible ignition source that could result in a fire.

Note: Drawings and pictures do not show the application one to one, but clarify the situation and approach reality

Inside the coating section the material passes multiple rollers and static is re-created. ATEX certified ionisation bars are neutralising the static charge on both sides of the web to prevent static charge acting as a possible ignition source. The pollution and efficiency level can be monitored by the IQ manager. If the efficiency goes below a preprogramed level the PLC or the operator receives a warning so he can service the indicated ionisation bars. During the drying process the material can re-charge again because of the temperature fluctuations in the dryer. Here and also before the laminating process 24V ionisation bars will neutralize the web and prevent static from encapsulating between the layers.

At the final (re)winder the material can once again create high static charges due to the pressure rollers, causing operators to get shocks when near to the material. As the distance to the material changes at the winder, a ThunderIon discharging bar is required to effectively eliminate the static charges created during the final winding. Additional demands regarding static charge or ensuring personnel safety can be created using an IQ Manager System with in-line static measurement and Closed Loop Feedback-technology. The IQ Manager can be directly connected to the coating lines PLC via Fieldbus connection. An alarm level alerts the operator in case the static charge reaches a dangerous level. In-line measuring and datalogging of static charge levels can be used in quality reporting. This is how the Manager IQ System provides all essential information to increase personnel safety and reduces the chance on new fires to a minimum.

Interested to learn more about the effect of static electricity?

Find a Simco representative near youor subscribe to the Simco Europe Youtube channel